🍪 This website requires cookies to provide all of it's features. Please enable your browser cookies.

Accept All Decline AllCompared with other material, Bronze valves are good choices for industries which require the following characteristics: Desalination and Highly corrosive environments.Sedelon manufactures different types of Bronze valves which are suitable for Chemical and Oil Industries, Sea Water Service, Desalination Plants, Off-Shore and Platforms.

Compared

with other material, Bronze valves are good choices for industries which

require the following characteristics: Desalination and Highly corrosive

environments.Sedelon manufactures different types of Bronze valves which are

suitable for Chemical and Oil Industries, Sea Water Service, Desalination

Plants, Off-Shore and Platforms.

Sedelon® mainly produces Bronze valves

according to the standard of API 600. We call them API 600 Bronze

valves.According to different design standards, Sedelon® provides you DIN

Bronze valves as well, for example, DIN Bronze Strainer valves.

The

characteristics of the Sedelon Bronze valves are of corrosion resistance ,

oxidation resistance , electric resistance and clean sanitation.

These features make Bronze valves special and incomparable to other metal

material valves.

Application

Face to Face Dimensions: ANSI B16.10

Flange end Dimension :ANSI B16.5

Butt Welded Dimensions:ANSI B16.25

Design and Manufacture:ANSI B16.34

Pressure Test:API 598

Materials:C95800、C95500、C95200、C95300、C95600、C61900、C63200,ect.

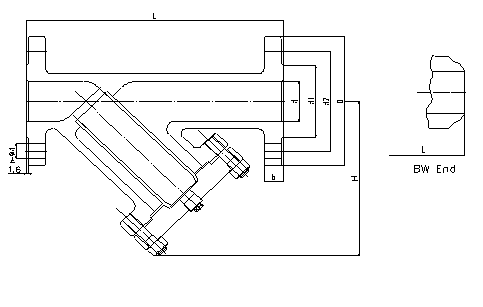

Class150 BronzeY-Type Strainer Valve

| NPS | in | 1/2 | 3/4 | 1 | 11/2 | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 |

| d | mm | 13 | 19 | 25 | 38 | 51 | 64 | 76 | 102 | 152 | 203 | 254 | 305 |

| L(RF) | mm | 140 | 152 | 165 | 203 | 229 | 279 | 318 | 368 | 470 | 597 | 673 | 775 |

| L(BW) | mm | 140 | 152 | 165 | 203 | 229 | 279 | 318 | 368 | 470 | 597 | 673 | 775 |

| d1 | mm | 35 | 43 | 51 | 73 | 92 | 105 | 127 | 157 | 216 | 270 | 324 | 381 |

| d2 | mm | 60.5 | 70 | 79.5 | 98.5 | 120.5 | 139.5 | 152.5 | 190.5 | 241.5 | 298.5 | 362 | 432 |

| D | mm | 89 | 98 | 108 | 127 | 152 | 178 | 190 | 229 | 279 | 343 | 406 | 483 |

| b | mm | 11 | 12 | 12 | 15 | 16 | 18 | 19 | 24 | 26 | 29 | 31 | 32 |

| n-Фd | mm | 4-16 | 4-16 | 4-16 | 4-16 | 4-19 | 4-19 | 4-19 | 8-19 | 8-22 | 8-22 | 12-25 | 12-25 |

| H | mm | 87 | 105 | 114 | 156 | 180 | 260 | 293 | 324 | 448 | 535 | 690 | 780 |

Class300 BronzeY-Type Strainer Valve

| NPS | in | 1/2 | 3/4 | 1 | 11/2 | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 |

| d | mm | 13 | 19 | 25 | 38 | 51 | 64 | 76 | 102 | 152 | 203 | 254 | 305 |

| L(RF) | mm | 140 | 152 | 165 | 203 | 229 | 279 | 318 | 368 | 470 | 597 | 673 | 775 |

| L(BW) | mm | 140 | 152 | 165 | 203 | 229 | 279 | 318 | 368 | 470 | 597 | 673 | 775 |

| d1 | mm | 35 | 43 | 51 | 73 | 92 | 105 | 127 | 157 | 216 | 270 | 324 | 381 |

| d2 | mm | 66.5 | 82.5 | 89 | 114.5 | 127 | 149 | 168.5 | 200 | 270 | 330 | 387.5 | 451 |

| D | mm | 95 | 117 | 124 | 156 | 165 | 190 | 210 | 254 | 318 | 381 | 445 | 521 |

| b | mm | 15 | 16 | 18 | 21 | 23 | 26 | 29 | 32 | 37 | 42 | 48 | 51 |

| n-Фd | mm | 4-16 | 4-19 | 4-19 | 4-22 | 8-19 | 8-22 | 8-22 | 8-22 | 12-22 | 12-25 | 16-29 | 16-32 |

| H | mm | 87 | 105 | 114 | 156 | 180 | 260 | 293 | 324 | 448 | 535 | 690 | 780 |

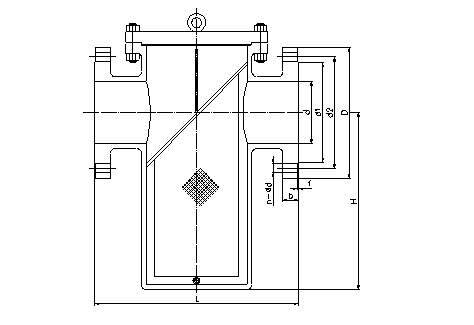

Class150 BronzeT-TypeStrainer Valve

| NPS | in | 1 | 11/2 | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 |

| d | mm | 25 | 38 | 51 | 64 | 76 | 102 | 152 | 203 | 254 | 305 |

| L(RF) | mm | 180 | 260 | 260 | 330 | 340 | 400 | 500 | 560 | 660 | 750 |

| d1 | mm | 51 | 73 | 92 | 105 | 127 | 157 | 216 | 270 | 324 | 381 |

| d2 | mm | 79.5 | 98.5 | 120.5 | 139.5 | 152.5 | 190.5 | 241.5 | 298.5 | 362 | 432 |

| D | mm | 108 | 127 | 152 | 178 | 190 | 229 | 279 | 343 | 406 | 483 |

| b | mm | 12 | 15 | 16 | 18 | 19 | 24 | 26 | 29 | 31 | 32 |

| n-Фd | mm | 4-16 | 4-16 | 4-19 | 4-19 | 4-19 | 8-19 | 8-22 | 8-22 | 12-25 | 12-25 |

| H | mm | 165 | 175 | 175 | 210 | 255 | 300 | 425 | 525 | 600 | 680 |

Class300 BronzeT-ypeStrainer Valve

| NPS | in | 1 | 11/2 | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 |

| d | mm | 25 | 38 | 51 | 64 | 76 | 102 | 152 | 203 | 254 | 305 |

| L(RF) | mm | 180 | 260 | 260 | 330 | 340 | 400 | 500 | 560 | 660 | 750 |

| d1 | mm | 51 | 73 | 92 | 105 | 127 | 157 | 216 | 270 | 324 | 381 |

| d2 | mm | 89 | 114.5 | 127 | 149 | 168.5 | 200 | 270 | 330 | 387.5 | 451 |

| D | mm | 124 | 156 | 165 | 190 | 210 | 254 | 318 | 381 | 445 | 521 |

| b | mm | 18 | 21 | 23 | 26 | 29 | 32 | 37 | 42 | 48 | 51 |

| n-Фd | mm | 4-19 | 4-22 | 8-19 | 8-22 | 8-22 | 8-22 | 12-22 | 12-25 | 16-29 | 16-32 |

| H | mm | 165 | 175 | 175 | 210 | 255 | 300 | 425 | 525 | 600 | 680 |

Face to Face Dimensions:ANSI B16.10

Flange end Dimension :ANSI B16.5

Butt Welded Dimensions:ANSI B16.25

Design and Manufacture:API 6D

Pressure Test:API598

Materials:A105、 F304 、F304L 、F316 、F316L、LF1 、LF2、LF3、LF9、 F51、F53、F11、F22, ect.

Face to Face Dimensions: ANSI B16.10

Flange end Dimension :ANSI B16.5

Butt Welded Dimensions:ANSI B16.25

Design and Manufacture:API 609

Pressure Test:API598

Materials:CF8、 CF8M、 CF3、 CF3M 、Monel、20# Alloys、4A、5A, ect.

Corporate Mission: Create Value for Clients, Create Opportunities for Staff, Create Efficiency for Corporate, Create wealth for Society.Quality+Service=Satisfaction.