🍪 This website requires cookies to provide all of it's features. Please enable your browser cookies.

Accept All Decline AllApplication

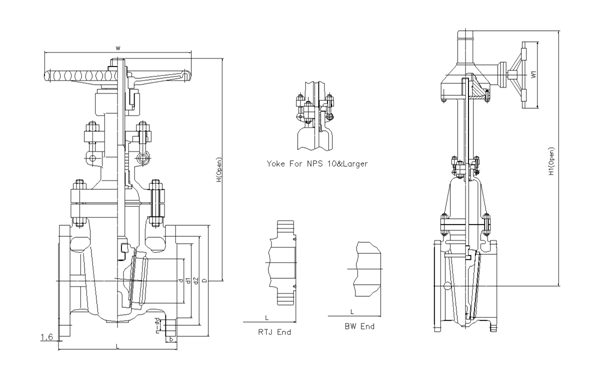

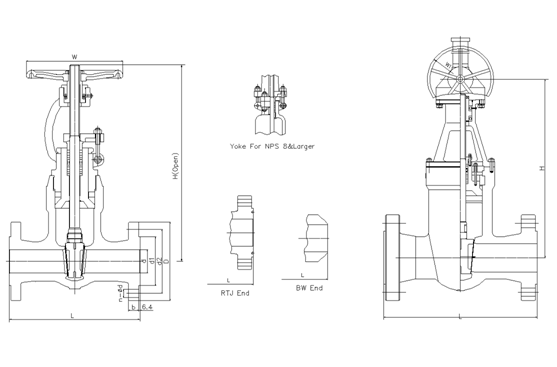

Face to Face Dimensions:ANSI B16.10

Flange end Dimension :ANSI B16.5

Butt Welded Dimensions:ANSI B16.25

Design and Manufacture:API 600

Pressure Test:API 598

Main material: WCB 、WC6 、WC9 、CF8、 CF8M、 CF3、 CF3M 、CN7M、LC1、LC2、LC3、LCB、LCC、Monel、 20# Alloys、4A、5A、C95800、C95500, ect.

Class150 Cast Steel

Gate Valve

| NPS | in | 2 | 2 1/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 |

| d | mm | 51 | 64 | 76 | 102 | 127 | 152 | 203 | 254 | 305 | 337 | 387 | 438 | 489 | 591 |

| L(RF) | mm | 178 | 190 | 203 | 229 | 254 | 267 | 292 | 330 | 356 | 381 | 406 | 432 | 457 | 508 |

| L(BW) | mm | 216 | 241 | 283 | 305 | 381 | 403 | 419 | 457 | 502 | 572 | 610 | 660 | 711 | 813 |

| L(RTJ) | mm | 191 | 203 | 216 | 241 | 267 | 279 | 305 | 343 | 368 | 394 | 419 | 445 | 470 | 521 |

| d1 | mm | 92 | 105 | 127 | 157 | 186 | 216 | 270 | 324 | 381 | 413 | 470 | 533 | 584 | 692 |

| d2 | mm | 120.5 | 139.5 | 152.5 | 190.5 | 216 | 241.5 | 298.5 | 362 | 432 | 476 | 540 | 578 | 635 | 749.5 |

| D | mm | 152 | 178 | 190 | 229 | 254 | 279 | 343 | 406 | 483 | 533 | 597 | 635 | 699 | 813 |

| b | mm | 16 | 18 | 19 | 24 | 24 | 26 | 29 | 31 | 32 | 35 | 37 | 40 | 43 | 48 |

| n-Фd | mm | 4-19 | 4-19 | 4-19 | 8-19 | 8-22 | 8-22 | 8-22 | 12-25 | 12-25 | 12-29 | 16-29 | 16-32 | 20-32 | 20-35 |

| H | mm | 400 | 435 | 515 | 595 | 725 | 780 | 975 | 1150 | 1380 | 1545 | 1733 | 1915 | 2122 | 2520 |

| H1 | mm |

|

|

|

|

| 820 | 1020 | 1200 | 1430 | 1580 | 1780 | 1990 | 2220 | 2600 |

| W | mm | 200 | 200 | 250 | 280 | 280 | 300 | 350 | 400 | 450 | 500 | 500 | 500 | 600 | 600 |

| W1 | mm |

|

|

|

|

| 310 | 310 | 310 | 310 | 310 | 460 | 460 | 460 | 460 |

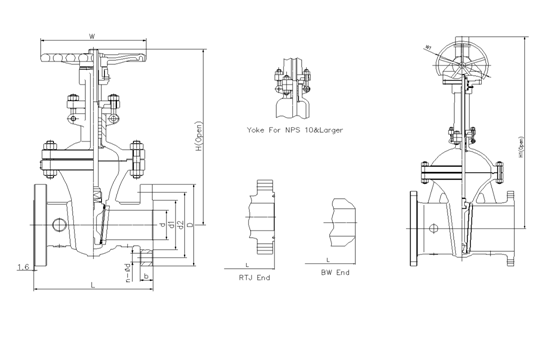

Class300 Cast Steel Gate Valve

| NPS | in | 2 | 2 1/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 |

| d | mm | 51 | 64 | 76 | 102 | 127 | 152 | 203 | 254 | 305 | 337 | 387 | 432 | 483 | 584 |

| L(RF) | mm | 216 | 241 | 283 | 305 | 381 | 403 | 419 | 457 | 502 | 762 | 838 | 914 | 991 | 1143 |

| L(BW) | mm | 216 | 241 | 283 | 305 | 381 | 403 | 419 | 457 | 502 | 762 | 838 | 914 | 991 | 1143 |

| L(RTJ) | mm | 232 | 257 | 298 | 321 | 397 | 419 | 435 | 473 | 518 | 778 | 854 | 930 | 1010 | 1165 |

| d1 | mm | 92 | 105 | 127 | 157 | 186 | 216 | 270 | 324 | 381 | 413 | 470 | 533 | 584 | 692 |

| d2 | mm | 127 | 149 | 168.5 | 200 | 235 | 270 | 330 | 387.5 | 451 | 514.5 | 571.5 | 628.5 | 686 | 813 |

| D | mm | 165 | 190 | 210 | 254 | 279 | 318 | 381 | 445 | 521 | 584 | 648 | 711 | 775 | 914 |

| b | mm | 23 | 26 | 29 | 32 | 35 | 37 | 42 | 48 | 51 | 54 | 58 | 61 | 64 | 70 |

| n-Фd | mm | 8-19 | 8-22 | 8-22 | 8-22 | 8-22 | 12-22 | 12-25 | 16-29 | 16-32 | 20-32 | 20-35 | 24-35 | 24-35 | 24-41 |

| H | mm | 420 | 446 | 537 | 619 | 722 | 806 | 1000 | 1240 | 1425 | 1585 | 1790 | 1960 | 2158 | 2576 |

| H1 | mm |

|

|

| 650 | 750 | 835 | 1030 | 1280 | 1460 | 1620 | 1830 | 2000 | 2220 | 2620 |

| W | mm | 200 | 200 | 250 | 280 | 300 | 350 | 400 | 450 | 500 | 500 | 600 | 650 | 750 | 900 |

| W1 | mm |

|

|

| 310 | 310 | 310 | 310 | 310 | 310 | 460 | 460 | 460 | 460 | 600 |

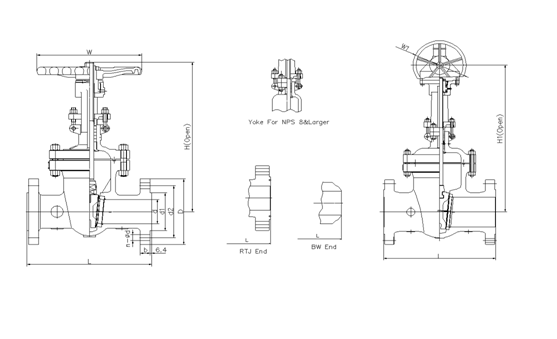

Class600 Cast Steel Gate Valve

| NPS | in | 2 | 2 1/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 |

| d | mm | 51 | 64 | 76 | 102 | 127 | 152 | 200 | 248 | 298 | 327 | 375 | 419 | 464 | 559 |

| L(RF) | mm | 292 | 330 | 356 | 432 | 508 | 559 | 660 | 787 | 838 | 889 | 991 | 1092 | 1194 | 1397 |

| L(BW) | mm | 292 | 330 | 356 | 432 | 508 | 559 | 660 | 787 | 838 | 889 | 991 | 1092 | 1194 | 1397 |

| L(RTJ) | mm | 295 | 333 | 359 | 435 | 511 | 562 | 664 | 791 | 841 | 892 | 994 | 1095 | 1200 | 1407 |

| d1 | mm | 92 | 105 | 127 | 157 | 186 | 216 | 270 | 324 | 381 | 413 | 470 | 533 | 584 | 692 |

| d2 | mm | 127 | 149 | 168.5 | 216 | 267 | 292 | 349 | 432 | 489 | 527 | 603 | 654 | 724 | 838 |

| D | mm | 165 | 190 | 210 | 273 | 330 | 356 | 419 | 508 | 559 | 603 | 686 | 743 | 813 | 940 |

| b | mm | 26 | 29 | 32 | 38 | 45 | 48 | 56 | 64 | 67 | 70 | 77 | 83 | 89 | 102 |

| n-Фd | mm | 8-19 | 8-22 | 8-22 | 8-25 | 8-29 | 12-29 | 12-32 | 16-35 | 20-35 | 20-38 | 20-41 | 20-44 | 24-44 | 24-52 |

| H | mm | 444 | 500 | 558 | 665 | 760 | 868 | 1073 | 1263 | 1600 | 1705 | 1835 |

|

|

|

| H1 | mm |

|

| 585 | 695 | 790 | 900 | 1110 | 1300 | 1650 | 1750 | 1900 | 2020 | 2172 | 2650 |

| W | mm | 200 | 250 | 280 | 300 | 350 | 450 | 500 | 650 | 700 | 900 | 900 |

|

|

|

| W1 | mm |

|

| 310 | 310 | 310 | 310 | 310 | 460 | 460 | 460 | 460 | 600 | 600 | 600 |

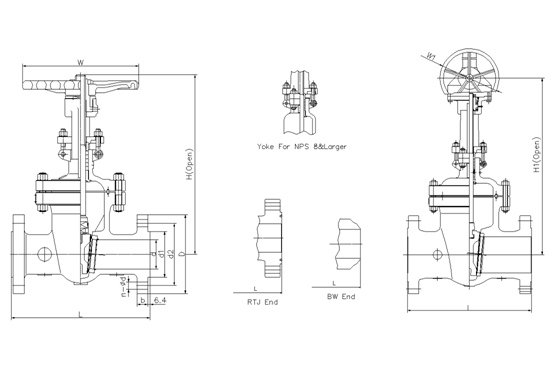

Class900 Cast Steel Gate Valve

| NPS | in | 2 | 2 1/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 |

| d | mm | 47 | 57 | 73 | 98 | 121 | 146 | 190 | 234 | 282 | 311 | 354 | 400 | 444 | 533 |

| L(RF) | mm | 368 | 419 | 381 | 457 | 559 | 610 | 737 | 838 | 965 | 1029 | 1130 | 1219 | 1321 | 1549 |

| L(BW) | mm | 368 | 419 | 381 | 457 | 559 | 610 | 737 | 838 | 965 | 1029 | 1130 | 1219 | 1321 | 1549 |

| L(RTJ) | mm | 371 | 422 | 384 | 460 | 562 | 613 | 740 | 841 | 968 | 1039 | 1140 | 1232 | 1334 | 1568 |

| d1 | mm | 92 | 105 | 127 | 157 | 186 | 216 | 270 | 324 | 381 | 413 | 470 | 533 | 584 | 692 |

| d2 | mm | 165 | 190.5 | 190.5 | 235 | 279.4 | 317.5 | 393.7 | 469.9 | 533.4 | 558.8 | 615.9 | 685.8 | 749.3 | 901.7 |

| D | mm | 216 | 244 | 241 | 292 | 349 | 381 | 470 | 545 | 610 | 640 | 705 | 785 | 855 | 1040 |

| b | mm | 38.5 | 41.5 | 38.5 | 44.5 | 51 | 56 | 64 | 70 | 79.5 | 86 | 89 | 102 | 108 | 140 |

| n-Фd | mm | 8-26 | 8-29 | 8-26 | 8-32 | 8-35 | 12-32 | 12-39 | 16-39 | 20-39 | 20-42 | 20-45 | 20-51 | 20-54 | 20-67 |

| H | mm | 500 | 550 | 610 | 702 | 850 | 980 | 1100 | 1320 | 1500 | 1900 | 2050 |

|

|

|

| H1 | mm |

|

| 660 | 750 | 900 | 1060 | 1140 | 1370 | 1560 | 1950 | 2100 | 2300 | 2450 | 2600 |

| W | mm | 280 | 280 | 300 | 350 | 400 | 500 | 650 | 700 | 900 | 900 | 900 |

|

|

|

| W1 | mm |

|

| 310 | 310 | 310 | 460 | 460 | 460 | 460 | 600 | 600 | 600 | 600 | 600 |

Class1500 Cast Steel Gate Valve

| NPS | in | 2 | 2 1/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 |

| d | mm | 47 | 57 | 70 | 92 | 111 | 136 | 178 | 222 | 263 | 289 | 330 |

| L(RF) | mm | 368 | 419 | 470 | 546 | 673 | 705 | 832 | 991 | 1130 | 1257 | 1384 |

| L(BW) | mm | 368 | 419 | 470 | 546 | 673 | 705 | 832 | 991 | 1130 | 1257 | 1384 |

| L(RTJ) | mm | 371 | 422 | 473 | 549 | 676 | 711 | 841 | 1000 | 1146 | 1276 | 1407 |

| d1 | mm | 92 | 105 | 127 | 157 | 186 | 216 | 270 | 324 | 381 | 413 | 470 |

| d2 | mm | 165 | 190.5 | 203.2 | 241.3 | 292.1 | 317.5 | 393.7 | 482.6 | 571.5 | 635 | 704.8 |

| D | mm | 216 | 244 | 267 | 311 | 375 | 394 | 483 | 585 | 675 | 750 | 825 |

| b | mm | 38.5 | 41.5 | 48 | 54 | 73.5 | 83 | 92.9 | 108 | 124 | 133.5 | 146.5 |

| n-Фd | mm | 8-26 | 8-29 | 8-32 | 8-35 | 8-42 | 12-39 | 12-45 | 12-51 | 16-54 | 16-61 | 16-67 |

| H | mm | 510 | 560 | 620 | 728 | 870 | 1000 | 1130 | 1360 |

|

|

|

| H1 | mm |

|

| 670 | 770 | 920 | 1070 | 1180 | 1410 | 1620 | 2020 | 2180 |

| W | mm | 280 | 300 | 350 | 400 | 450 | 500 | 750 | 900 |

|

|

|

| W1 | mm |

|

| 310 | 310 | 310 | 460 | 460 | 600 | 600 | 600 | 600 |

Class2500 Cast Steel Gate Valve

| NPS | in | 2 | 2 1/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 |

| d | mm | 38 | 47 | 57 | 73 | 92 | 111 | 146 | 184 | 219 |

| L(RF) | mm | 451 | 508 | 578 | 673 | 794 | 914 | 1022 | 1270 | 1422 |

| L(BW) | mm | 451 | 508 | 578 | 673 | 794 | 914 | 1022 | 1270 | 1422 |

| L(RTJ) | mm | 454 | 514 | 584 | 683 | 807 | 927 | 1038 | 1292 | 1445 |

| d1 | mm | 92 | 105 | 127 | 157 | 186 | 216 | 270 | 324 | 381 |

| d2 | mm | 171.4 | 196.8 | 228.6 | 273 | 323.8 | 368.3 | 438.1 | 539.7 | 619.1 |

| D | mm | 235 | 267 | 305 | 356 | 419 | 483 | 550 | 675 | 760 |

| b | mm | 51 | 57.5 | 67 | 76.5 | 92.5 | 108 | 127 | 165.5 | 184.5 |

| n-Фd | mm | 8-29 | 8-32 | 8-35 | 8-42 | 8-48 | 8-54 | 12-54 | 12-67 | 12-74 |

| H | mm | 530 | 580 | 650 | 750 | 900 | 1040 | 1150 | 1400 |

|

| H1 | mm | 580 | 630 | 700 | 800 | 960 | 1100 | 1200 | 1460 | 1660 |

| W | mm | 280 | 300 | 350 | 400 | 500 | 600 | 750 | 900 |

|

| W1 | mm | 310 | 310 | 310 | 310 | 460 | 460 | 460 | 600 | 600 |

API Trim NO. Table

|

No |

Seat |

Gate、disc 、ball or body |

Stem |

No |

Seat |

Gate、disc 、ball or body |

Stem | |

| 01 | 13Cr | 13Cr | 13Cr | 31 | STELLITE | 321SS | 321SS | |

| 02 | 304SS | 304SS | 304SS | 32 | STELLITE | STELLITE | 321SS | |

| 03 | 310SS | 310SS | 310SS | 33 | 347SS | 347SS | 347SS | |

| 04 | HARD 13Cr | HARD 13Cr | 13Cr | 34 | STELLITE | 347SS | 347SS | |

| 05 | STELLITE | STELLITE | 13Cr | 35 | NICKEL ALLOY | 13Cr | 13Cr | |

| 06 | Cu-Ni | 13Cr | 13Cr | 36 | A105/PTFE | A105+ENP | A105+ENP | |

| 07 | 13Cr | HARD 13Cr | 13Cr | 37 | A105/PTFE | WCB+ENP | A105+ENP | |

| 08 | STELLITE | 13Cr | 13Cr | 38 | 13Cr/PTFE | 13Cr | 13Cr | |

| 09 | Cu-Ni | Cu-Ni | Cu-Ni | 39 | 304SS/PTFE | 304SS | 304SS | |

| 10 | 316SS | 316SS | 316SS | 40 | 316SS/PTFE | 316SS | 316SS | |

| 11 | Cu-Ni | STELLITE | Cu-Ni | 41 | A105/RPTFE | A105+ENP | A105+ENP | |

| 12 | STELLITE | 316SS | 316SS | 42 | A105/RPTFE | WCB+ENP | A105+ENP | |

| 13 | ALLOY 20 | ALLOY 20 | ALLOY 20 | 43 | 13Cr/RPTFE | 13Cr | 13Cr | |

| 14 | STELLITE | ALLOY 20 | ALLOY 20 | 44 | 304SS/RPTFE | 304SS | 304SS | |

| 15 | STELLITE | STELLITE | 304SS | 45 | 316SS/RPTFE | 316SS | 316SS | |

| 16 | STELLITE | STELLITE | 316SS | 46 | A105/NYLON | A105+ENP | A105+ENP | |

| 17 | STELLITE | STELLITE | 347SS | 47 | A105/NYLON | WCB+ENP | A105+ENP | |

| 18 | STELLITE | STELLITE | ALLOY 20 | 48 | A105/NYLON | 304SS | 304SS | |

| 19 | MONEL | MONEL | MONEL | 49 | A105/NYLON | 316SS | 316SS | |

| 20 | BRONZE | BRONZE | 13Cr | 50 | 13Cr/NYLON | 13Cr | 13Cr | |

| 21 | HASTELLOY B | HASTELLOY B | HASTELLOY B | 51 | 304SS/NYLON | 304SS | 304SS | |

| 22 |

| HASTELLOY C | HASTELLOY C | 52 | 316SS/NYLON | 316SS | 316SS | |

| 23 | STELLITE | 304SS | 304SS | 53 | A105/PEEK | A105+ENP | A105+ENP | |

| 24 | 304LSS | 304LSS | 304LSS | 54 | A105/PEEK | WCB+ENP | A105+ENP | |

| 25 | STELLITE | 304LSS | 304LSS | 55 | 13Cr/PEEK | 13Cr | 13Cr | |

| 26 | STELLITE | STELLITE | 304LSS | 56 | 304SS/PEEK | 304SS | 304SS | |

| 27 | 316LSS | 316LSS | 316LSS | 57 | 316SS/PEEK | 316SS | 316SS | |

| 28 | STELLITE | 316LSS | 316LSS |

|

|

|

|

|

| 29 | STELLITE | STELLITE | 316LSS |

|

|

| ||

| 30 | 321SS | 321SS | 321SS |

|

|

|

| |

Note:please indicate it directly in the

order for the internal part’smaterial uncovered in the table

Compared with other material, Bronze valves are good choices for industries which require the following characteristics: Desalination and Highly corrosive environments.Sedelon manufactures different types of Bronze valves which are suitable for Chemical and Oil Industries, Sea Water Service, Desalination Plants, Off-Shore and Platforms.

Compared with other material, Bronze valves are good choices for industries which require the following characteristics: Desalination and Highly corrosive environments.Sedelon manufactures different types of Bronze valves which are suitable for Chemical and Oil Industries, Sea Water Service, Desalination Plants, Off-Shore and Platforms.

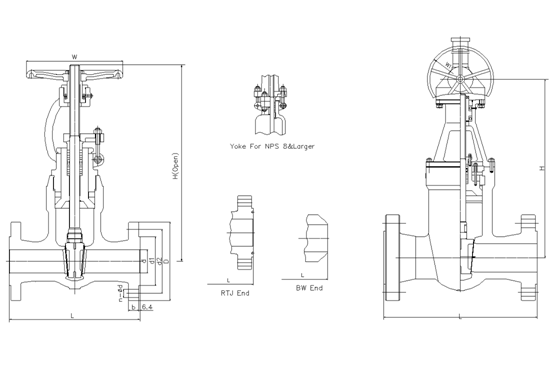

Face to Face Dimensions:ANSI B16.10

Flange end Dimension :ANSI B16.5

Butt Welded Dimensions:ANSI B16.25

Design and Manufacture:API 6D

Pressure Test:API598

Materials:A105、 F304 、F304L 、F316 、F316L、LF1 、LF2、LF3、LF9、 F51、F53、F11、F22, ect.

Corporate Mission: Create Value for Clients, Create Opportunities for Staff, Create Efficiency for Corporate, Create wealth for Society.Quality+Service=Satisfaction.