🍪 This website requires cookies to provide all of it's features. Please enable your browser cookies.

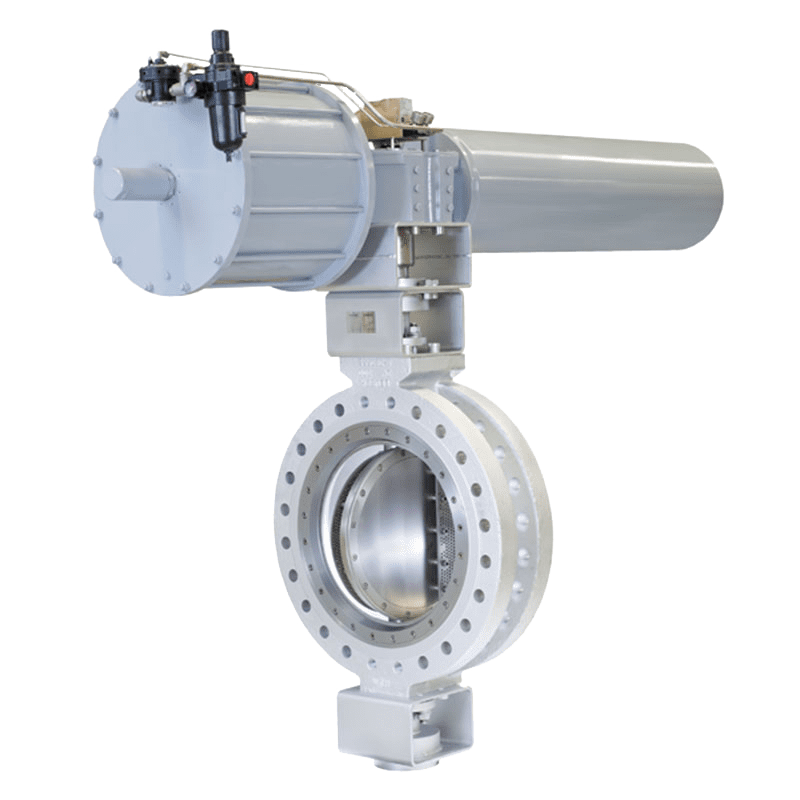

Accept All Decline All1.Concentric, high-performance, double eccentric, triple offset, etc.

2.Simple structure, small fluid resistance, quick opening and closing

3.Available with soft-seal seat and metal to metal seat

Sedelon® Butterfly valves are versatile flow control devices designed for various media, including corrosive environments. Made from Forged Steel, Stainless Steel, special alloys like Hastelloy, and ceramics, they offer enhanced erosion and wear resistance.

Sedelon® produces API 609 Forged Steel and API 603 Stainless Steel valves, available in Wafer, Flanged, Lug-Style, and Welded connections. Operated by hand-wheel, gear, pneumatic, or motorized options, they suit various pressure and temperature conditions.

These valves are widely used in industries like oil, gas, chemicals, and shipbuilding for precise flow control and high-pressure applications.

Face to Face Dimensions: ANSI B16.10

Flange end Dimension :ANSI B16.5

Butt Welded Dimensions:ANSI B16.25

Design and Manufacture:API 609

Pressure Test:API598

Materials:WCB 、WC6 、WC9 、CF8、 CF8M、 CF3、 CF3M 、CN7M、LC1LC2、LC3、LCB、LCC、Monel、20# Alloys、4A、5A、C95800、C95500, ect.

Face to Face Dimensions: ANSI B16.10

Flange end Dimension :ANSI B16.5

Butt Welded Dimensions:ANSI B16.25

Design and Manufacture:API 609

Pressure Test:API598

Materials:WCB 、WC6 、WC9 、CF8、 CF8M、 CF3、 CF3M 、CN7M、LC1LC2、LC3、LCB、LCC、Monel、20# Alloys、4A、5A、C95800、C95500, ect.

Face to Face Dimensions: ANSI B16.10

Flange end Dimension :ANSI B16.5

Butt Welded Dimensions:ANSI B16.25

Design and Manufacture:API 609

Pressure Test:API598

Materials:CF8、 CF8M、 CF3、 CF3M 、CN7M、LC1LC2、LC3、LCB、LCC、Monel、20# Alloys、4A、5A、C95800、C95500, ect.

Face to Face Dimensions: ANSI B16.10

Flange end Dimension :ANSI B16.5

Butt Welded Dimensions:ANSI B16.25

Design and Manufacture:API 609

Pressure Test:API598

Materials:WCB 、WC6 、WC9 、CF8、 CF8M、 CF3、 CF3M 、CN7M、LC1LC2、LC3、LCB、LCC、Monel、20# Alloys、4A、5A、C95800、C95500, ect.

Face to Face Dimensions: ANSI B16.10

Flange end Dimension :ANSI B16.5

Butt Welded Dimensions:ANSI B16.25

Design and Manufacture:API 609

Pressure Test:API598

Materials:WCB 、WC6 、WC9 、CF8、 CF8M、 CF3、 CF3M 、CN7M、LC1LC2、LC3、LCB、LCC、Monel、20# Alloys、4A、5A、C95800、C95500, ect.

Face to Face Dimensions: ANSI B16.10

Flange end Dimension :ANSI B16.5

Butt Welded Dimensions:ANSI B16.25

Design and Manufacture:API 609

Pressure Test:API598

Materials: CF8、 CF8M、 CF3、 CF3M 、Monel、20# Alloys、4A、5A, ect.

Face to Face Dimensions: ANSI B16.10

Flange end Dimension :ANSI B16.5

Butt Welded Dimensions:ANSI B16.25

Design and Manufacture:API 609

Pressure Test:API598

Materials:WCB 、WC6 、WC9 、CF8、 CF8M、 CF3、 CF3M 、CN7M、LC1LC2、LC3、LCB、LCC、Monel、20# Alloys、4A、5A、C95800、C95500, ect.

Face to Face Dimensions: ANSI B16.10

Flange end Dimension :ANSI B16.5

Butt Welded Dimensions:ANSI B16.25

Design and Manufacture:API 609

Pressure Test:API598

Materials:WCB 、WC6 、WC9 、CF8、 CF8M、 CF3、 CF3M 、CN7M、LC1LC2、LC3、LCB、LCC、Monel、20# Alloys、4A、5A、C95800、C95500, ect.

Face to Face Dimensions: ANSI B16.10

Flange end Dimension :ANSI B16.5

Butt Welded Dimensions:ANSI B16.25

Design and Manufacture:API 609

Pressure Test:API598

Materials:WCB 、WC6 、WC9 、CF8、 CF8M、 CF3、 CF3M 、CN7M、LC1LC2、LC3、LCB、LCC、Monel、20# Alloys、4A、5A、C95800、C95500, ect.

Sedelon is your reliable industrial valve manufacturer. We have a trusted supply network as well as we offer the latest production and assembly machinery. Here are the reasons why you should choose us as your industrial valve supplier.

Sedelon supports many industrial applications because we manufacture an extensive range of industrial valves,including butterfly, ball, check, gate, globe, plug, and actuated valves.

We offer tailor-made industrial valves to ensure that our product fits your application standards and demand.Sedelon is lSO, APl, MSS and ASME compliant to guarantee you the highest product quality.

Our industrial valves and services comply with international standards and specifications to make sure that we only produce the best and highest quality products and services to our clients.

As a business partner, Sedelon makes sure that we commit to our clients’ requested deadline because we very much understand the importance of adhering to the timeline required.

Corporate Mission: Create Value for Clients, Create Opportunities for Staff, Create Efficiency for Corporate, Create wealth for Society.Quality+Service=Satisfaction.