🍪 This website requires cookies to provide all of it's features. Please enable your browser cookies.

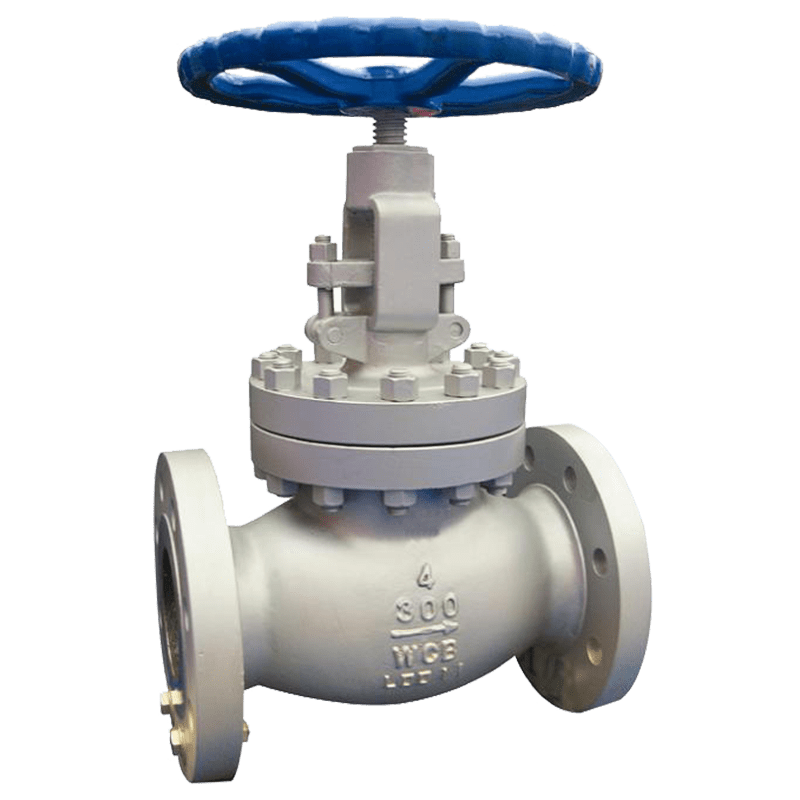

Accept All Decline All1.Available with plug disc, needle disc, parabolic disc, ball type disc, etc.

2.Available in structure of Y type, angle type, straight type, etc.

3.Simple structure, easy to repair and replace

4.Regulating flow in the pipeline

Sedelon® Globe valves are designed for the control of fluid flow, including opening, closing, and throttling. These valves come in various materials such as Forged Steel, Stainless Steel, Carbon Steel, and special alloys like Hastelloy and Duplex Stainless Steel to handle corrosive environments. The valves can be operated manually by hand wheels, through gears for larger sizes, or by actuators (electric, pneumatic, or hydraulic).

Sedelon® offers Globe valves with different connections like flanged, screwed, and welded, and also provides specialized types such as high-temperature, cryogenic, and pressure-seal Globe valves.

Widely used across industries handling fluids in high and low temperature environments, corrosive conditions, and where leakage prevention is critical, including LNG and LPG industries.

Face to Face Dimensions: EN558-1/DIN3202 F2

Flange end Dimension : EN1092-1/DIN2545

Design and Manufacture:EN 13709/DIN3356

Pressure Test:EN12266/DIN3230

Materials:WCB 、WC6 、WC9 、CF8、 CF8M、 CF3、 CF3M 、CN7M、LC1LC2、LC3、LCB、LCC、Monel、20# Alloys、4A、5A、C95800、C95500, ect.

Face to Face Dimensions:ANSI B16.10

Flange end Dimension :ANSI B16.5

Butt Welded Dimensions:ANSI B16.25

Design and Manufacture:BS1873

Pressure Test:API598

Materials: CF8、 CF8M、 CF3、 CF3M 、CN7M、LC1LC2、LC3、LCB、LCC、Monel、20# Alloys、4A、5A, ect.

Face to Face Dimensions:ANSI B16.10

Flange end Dimension :ANSI B16.5

Butt Welded Dimensions:ANSI B16.25

Design and Manufacture:API 602

Pressure Test:API 598Materials:A105、 F304 、F304L 、F316 、F316L、LF1 、LF2、LF3、LF9、 F51、F53、F11、F22

Face to Face Dimensions: EN558-1/DIN3202 F2

Flange end Dimension : EN1092-1/DIN2545

Design and Manufacture:EN 13709/DIN3356

Pressure Test:EN12266/DIN3230

Materials:WCB 、WC6 、WC9 、CF8、 CF8M、 CF3、 CF3M 、CN7M、LC1LC2、LC3、LCB、LCC、Monel、20# Alloys、4A、5A、C95800、C95500, ect.

Face to Face Dimensions:ANSI B16.10

Flange end Dimension :ANSI B16.5

Butt Welded Dimensions:ANSI B16.25

Design and Manufacture:BS1873

Pressure Test:API598

Materials:WC6 、WC9 、CF8、 CF8M、 CF3、 CF3M 、CN7M、LC1LC2、LC3、LCB、LCC、Monel、20# Alloys、4A、5A、C95800、C95500, ect.

Face to Face Dimensions:ANSI B16.10

Flange end Dimension :ANSI B16.5

Butt Welded Dimensions:ANSI B16.25

Design and Manufacture:BS1873

Pressure Test:API598

Materials:WCB、WC6 、WC9 、CF8、 CF8M、 CF3、 CF3M 、CN7M、LC1LC2、LC3、LCB、LCC、Monel、20# Alloys、4A、5A、C95800、C95500, ect.

Nowadays, people pay much attention to environmental protection.

We Sedelon also take it into consideration.

Low Emission Globe valves /Low Leakage Globe valves can effectively prevent the medium leakage and emission, thus being good for the environment.

Equipped with Fugitive Emission Test Certificate ISO 15848-1:2006, Sedelon manufactures Fugitive Emission Globe valves in order to make a contribution to protecting the environment.

Face to Face Dimensions:ANSI B16.10

Flange end Dimension :ANSI B16.5

Butt Welded Dimensions:ANSI B16.25

Design and Manufacture:API 602

Pressure Test:API 598

Materials:A105、 F304 、F304L 、F316 、F316L、LF1 、LF2、LF3、LF9、 F51、F53、F11、F22

Face to Face Dimensions:ANSI B16.10

Flange end Dimension :ANSI B16.5

Butt Welded Dimensions:ANSI B16.25

Design and Manufacture:BS1873

Pressure Test:API598

Materials:WCB 、WC6 、WC9 、CF8、 CF8M、 CF3、 CF3M 、CN7M、LC1LC2、LC3、LCB、LCC、Monel、20# Alloys、4A、5A、C95800、C95500, ect.

Sedelon is your reliable industrial valve manufacturer. We have a trusted supply network as well as we offer the latest production and assembly machinery. Here are the reasons why you should choose us as your industrial valve supplier.

Sedelon supports many industrial applications because we manufacture an extensive range of industrial valves,including butterfly, ball, check, gate, globe, plug, and actuated valves.

We offer tailor-made industrial valves to ensure that our product fits your application standards and demand.Sedelon is lSO, APl, MSS and ASME compliant to guarantee you the highest product quality.

Our industrial valves and services comply with international standards and specifications to make sure that we only produce the best and highest quality products and services to our clients.

As a business partner, Sedelon makes sure that we commit to our clients’ requested deadline because we very much understand the importance of adhering to the timeline required.

Corporate Mission: Create Value for Clients, Create Opportunities for Staff, Create Efficiency for Corporate, Create wealth for Society.Quality+Service=Satisfaction.